The key to purification the harmful gas of diesel engines is to eliminate the NO x and PM emission. Improve fuel injection systems is undoubtedly the principal measure. The following are specific measures to control emissions:

1. Delay injection advance Angle to reduce NO x emission

Delay fuel injection, pressure, and temperature will be rising the ignition delay period are shortened, premixed fuel injection reduced. Reducing premixed oil and mixed gas will reduce the rising degree of pressure and temperature in the rapid burning period, thus reducing NO x emission.

2. High-pressure fuel injection to reduces PM emissions

(1) Reduce the emission of PM

The fuel injection pressure increases, the particle size decreases, the penetration distance increases, the fog cone Angle increases, the total volume in the spray area increases, the turbulence increases, fuel mixes better with air, the PM generation range decreases.

(2) Reduce fuel consumption rate

The fuel injection rate increases, the fuel injection period shortens, the combustion accelerates, and the fuel consumption rate decreases.

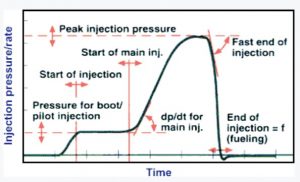

3. Control fuel injection rate

At the beginning of injection, a low injection rate and less injection quantity require to reduce NO X and noise. In the middle period of fuel injection, the brief and high fuel injection rate section requires improving fuel injection pressure, shorten the slow-burning period, promote the formation of a mixture, and reduce PM emission and fuel consumption. In the later period of oil injection, it required to end oil injection quickly to reduce rear fuel and promote soot oxidation.

4. Small diameter, multi-jet hole accelerated atomization mixed

At a constant injection rate, accelerate oil mixing with gas by reducing orifice diameter and increasing the flow coefficient of the injector hole to improve the emission effect.

5. Reduces the pressure chamber volume of orifice nozzle/Use no-pressure type nozzle

If the emission performance suddenly exacerbates when the engine is working, maybe the fuel injection system does not regularly work, therefore replace the parts can not delay.

Email: [email protected]

Whatsapp/Facebook/Wechat/Instagram: +86 17788932192